In the realm of heavy machinery maintenance, ensuring optimal performance and longevity of equipment is paramount. To address this need, advanced techniques such as Line Boring, on-site machining, and various forms of bore repair have become indispensable. These processes are complemented by slew milling, xy milling, and other detailed methods like bore welding, bush install, and face welding.

The Importance of Line Boring

Line Boring is a critical service used to repair or enlarge worn or misshapen bore holes within machinery. It ensures that bores are perfectly aligned, which is essential for the proper operation of the machine. Performing Line Boring on-site reduces downtime and transportation costs, making it a more efficient option for businesses.

On-Site Machining: The Game Changer

On-site machining offers an unparalleled advantage by enabling repair and maintenance work to be conducted directly at the equipment’s location. This reduces the need for disassembly and transportation, significantly cutting down on operational disruptions and associated costs.

Bore Repair and Bore Welding

Read more about Line Boring here.

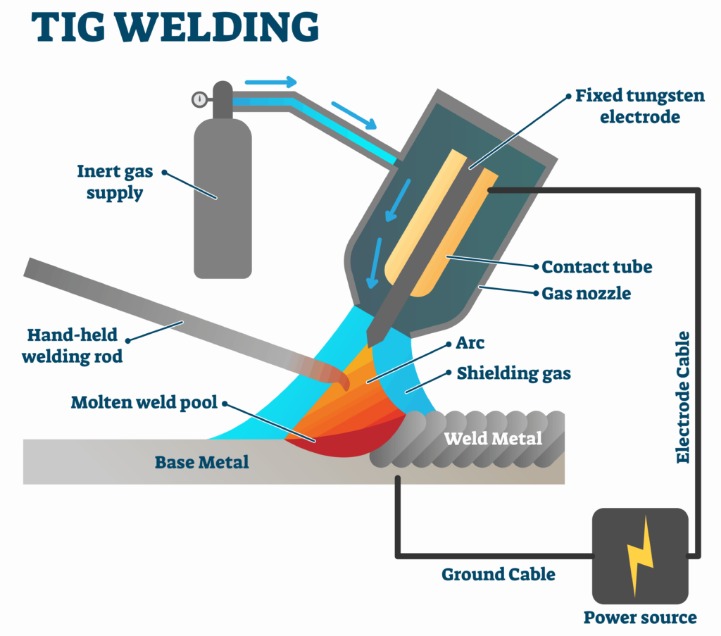

Over time, bore holes can experience wear and tear, leading to equipment inefficiency. Bore repair addresses this issue by restoring the bore to its original dimensions, ensuring smooth operation. Bore welding is commonly used in this repair process, where material is added to the worn area before being machined back to the correct size.

Slew Milling and XY Milling

For precision repair and component manufacturing, techniques like slew milling and xy milling are utilized. These methods are essential in cases where intricate geometrical features need to be accurately produced or restored. Slew milling is particularly useful for creating or refurbishing complex shapes, while xy milling allows for precise horizontal and vertical alignment.

Bush Install and Face Welding

Installing new bushes ensures the longevity and efficiency of moving parts within machinery. Proper alignment during bush install is critical to maintaining the integrity of the machine’s operation. Face welding further extends the lifespan of machinery components by applying a new surface layer to worn parts, providing protection against future wear and tear.

Conclusion

The integration of advanced techniques such as Line Boring, on-site machining, and bore repair, along with bore welding, slew milling, xy milling, bush install, and face welding, represents a significant evolution in heavy machinery maintenance. These methods not only enhance the performance and durability of equipment but also offer substantial cost savings and reduce operational downtime.