In the increasingly demanding fields of construction and heavy machinery maintenance, the need for precision repairs and adjustments has led to the evolution of several advanced on-site machining techniques. Among these, line boring, bore repair, bore welding, and slew milling are paramount. This article delves into these methodologies, offering insights into the tools and processes involved.

Line Boring: Achieving Perfect Alignment

Line boring is a critical technique used in heavy equipment maintenance and repair. This process involves the precision machining of bores to ensure they are perfectly aligned and sized. Key applications include:

- Repairing worn-out bores in heavy machinery

- Restoring the internal diameters of large engine blocks

- Aligning bores in process manufacturing equipment

On-Site Machining: Convenience Meets Precision

On-site machining eliminates the need for costly and time-consuming transport of large components to off-site facilities. Utilizing portable machines, technicians can perform precision bore repair and other tasks directly at the equipment’s location, ensuring minimum downtime and maximum efficiency.

Bore Repair and Bore Welding Techniques

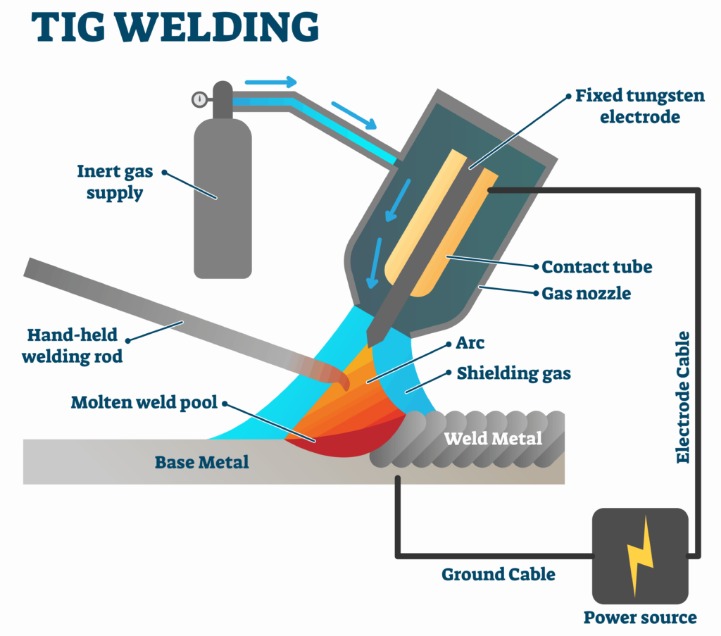

Bore repair typically involves restoring worn or damaged bores to their original specifications. When damage is extensive, bore welding is employed to deposit new material, which is then machined to precise dimensions. Steps include:

- Inspection and measurement of the damaged bore

- Preparation of the surface for welding

- Welding the bore back to its original thickness

- Machining the bore to the required dimensions

Slew Milling and XY Milling: Enhancing Precision Machining

Both slew milling and xy milling play pivotal roles in achieving high-precision results. Slew milling is used for machining large and irregular surfaces, while xy milling is ideal for detailed and intricate components. These techniques ensure accurate machining, which is essential for proper equipment functioning.

Bush Install and Face Welding: Crucial Complementary Techniques

Accurate bush installations are critical for seamless equipment performance. Bore machining is followed by bush install, which involves the precise fitting of bushes into repaired bores. Additionally, face welding is crucial in repairing or rebuilding the outer faces of components, ensuring smooth and uniform surfaces for effective functioning.

Frequently Asked Questions

Q1: What is the primary benefit of line boring?

A1: Line boring ensures the perfect alignment and size of bores, which is essential for the efficient operation of machinery.

Read more about Line Boring here.

Q2: How does on-site machining reduce downtime?

A2: By performing repairs and adjustments directly at the equipment’s location, on-site machining eliminates the need for component transport, significantly reducing downtime.

Q3: When is bore welding necessary?

A3: Bore welding is employed when the damage to a bore is significant, and new material needs to be deposited before machining to the required dimensions.

Q4: What are the key applications of slew milling?

A4: Slew milling is crucial for machining large, irregular surfaces, ensuring precision and effective functioning of the equipment.

Understanding and leveraging advanced machining and repair techniques such as line boring, bore repair, slew milling, and more, ensures optimal performance and longevity of heavy machinery and equipment. Employing these methods can significantly contribute to the efficiency and reliability of operations across various industries.